Welding of thermoplastics is accomplished in three sequential stages namely surface preparation application of heat and pressure and cooling.

Laser beam welding process can produce a temperature of the order degree celsius.

The laser beams are focused to the cavity between the two metal pieces to be joined.

When the metal is raised to its melting temperature the surface conditions have a minor effect on reflecting the beam.

Laser welding can usually join crack prone materials such as certain types of steel and aluminum and much like eb welding lasers can join dissimilar materials.

Being such a concentrated heat source in thin materials laser welding can be carried out at high welding speeds of metres per minute and in thicker materials can produce narrow deep welds between square edged parts.

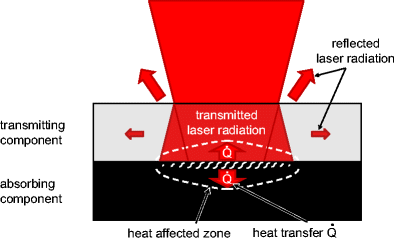

With this illustration you can see the process of laser welding at work.

Laser beam welding is a fusion welding process in which two metal pieces are joined together by the use of laser.

2013 used 15 kw co 2 laser welding system with a spot diameter of 0 8 mm to weld the tib 2 zl101 composite.

Lbm can be used to process these materials with intricate shapes and sizes with greater precision even difficult to reach surfaces.

As material selections in automotive manufacturing move further into the high strength realm along with the more prevalent usage of difficult to weld materials such as aluminum developing robust processes for joining these materials becomes ever more critical.

Deep in steel for a typical 350 watt laser.

Keys to laser welding lap and edge joints.

Sttir laser welding is a fast four step process 1 as two component parts are brought together under a specific force a beam of laser light is generated by the laser welder at a tuned wavelength.

The smooth rounded weld does not need to be processed further once the laser beam welding process is complete.

Heat conduction welding is used mostly to join parts with thin walls.

When using a laser beam for welding the beam strikes on the surface of the base metal with such a concentration of energy that the surface is melted and volatilized.

8 shows the possibility of the presence of al 3 ti b 2 o 3 alb 12 and tio 2 in the weld seam it illustrates that tib 2 particles are evolved into tio 2 and b 2 o 3 through the reaction with oxygen molecules in the laser welding process.

The xrd pattern fig.

The laser beam passes through the transmissive material of one component and is absorbed by the absorptive material of the component to be joined.

Laser welding is a process used to join together metals or thermoplastics using a laser beam to form a weld.

Laser beam welding process.

The laser beams have enough energy and when it strikes the metal pieces produce heat that melts the material from the two metal pieces and fills the cavity.